If you were to rewind and remember the architectural aesthetics of a typical Nepali house 100 years ago, concrete and steel would be absent. On our way to modernization, we have lost building techniques that not only suited Nepal’s climate best but was also strong and environmentally sustainable. As the number of cement/brick homes multiplied, the economy took a beating as 70 per cent of the materials used to build a ‘modern house’ were imported.

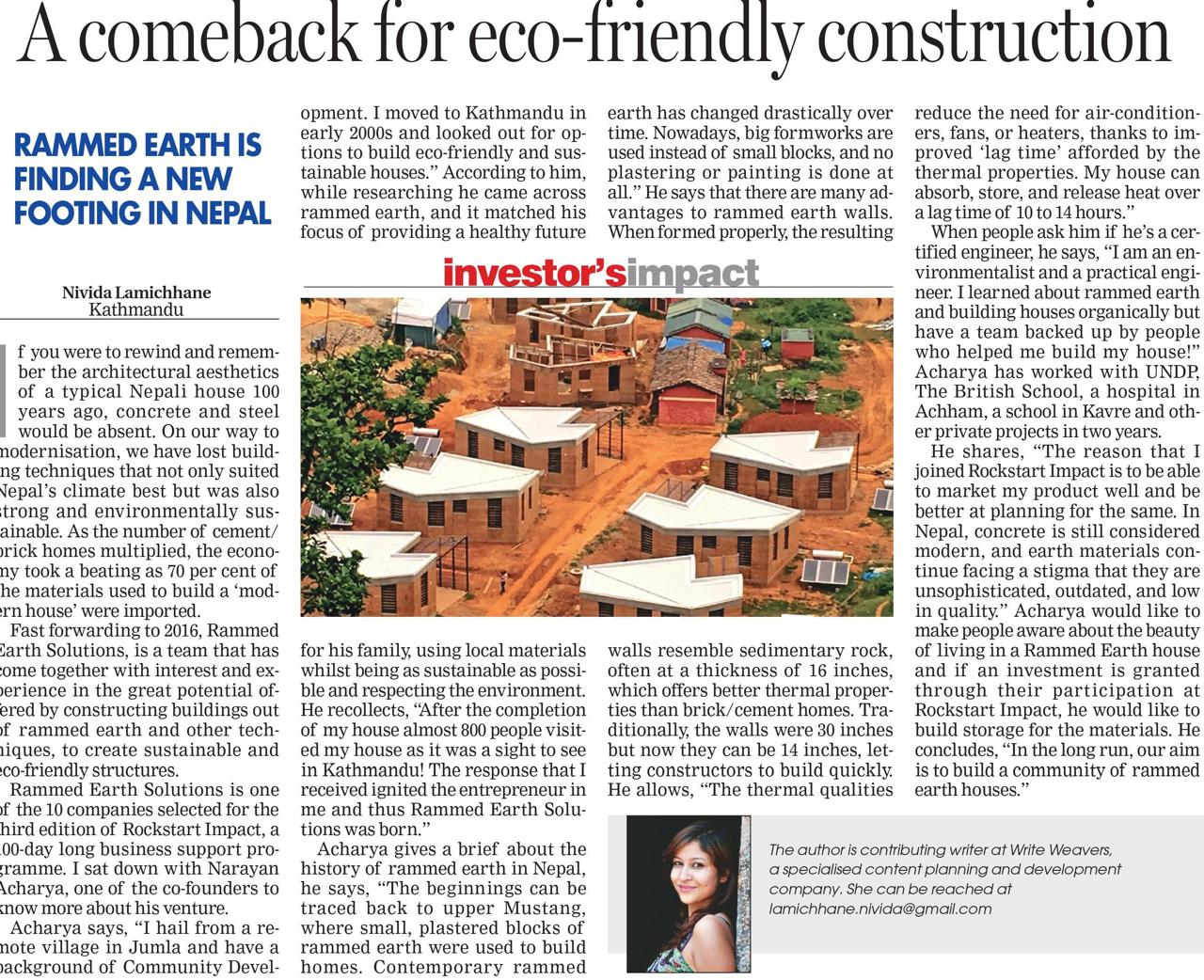

Fast forwarding to 2016, Rammed Earth Solutions, a team that has come together with interest and experience in the great potential offered by constructing buildings out of rammed earth and other techniques, to create sustainable and eco-friendly structures.

Rammed Earth Solutions is one of the 10 companies selected for the third edition of Rockstart Impact, a 100-day long business support programme. I sat down with Narayan Acharya, one of the co-founders to know more about his venture.

Acharya says, “I hail from a remote village in Jumla and have a background of Community Development. I moved to Kathmandu in early 2000s and looked out for options to build eco-friendly and sustainable houses.” According to him, while researching he came across rammed earth, and it matched his focus of providing a healthy future for his family, using local materials whilst being as sustainable as possible and respecting the environment.

He recollects, “After the completion of my house almost 800 people visited my house as it was a sight to see in Kathmandu! The response that I received ignited the entrepreneur in me and thus Rammed Earth Solutions was born.”

Acharya gives a brief about the history of rammed earth in Nepal, “The beginnings can be traced back to upper Mustang, where small, plastered blocks of rammed earth were used to build homes. Contemporary rammed earth has changed drastically over time. Nowadays, big formworks are used instead of small blocks, and no plastering or painting is done at all.” He says that there are many advantages to rammed earth walls. When formed properly, the resulting walls resemble sedimentary rock, often at a thickness of 16 inches, which offers better thermal properties than brick/cement homes. Traditionally, the walls were 30 inches but now they can be 14 inches, letting constructors to build quickly. He allows, “The thermal qualities reduce the need for air-conditioners, fans, or heaters, thanks to improved ‘lag time’ afforded by the thermal properties. My house can absorb, store, and release heat over a lag time of 10 to 14 hours.”

When people ask him if he’s a certified engineer, he says, “I am an environmentalist and a practical engineer. I learned about rammed earth and building houses organically but have a team backed up by people who helped me build my house!”

Acharya has worked with UNDP, The British School, a hospital in Achham, a school in Kavre and other private projects in two years.

He shares, “The reason that I joined Rockstart Impact is to be able to market my product well and be better at planning for the same. In Nepal, concrete is still considered modern, and earth materials continue facing a stigma that they are unsophisticated, outdated, and low in quality.” Acharya would like to make people aware about the beauty of living in a Rammed Earth house and if investment is granted through their participation at Rockstart Impact, he would like to build storage for the materials.

He concludes, “In the long run, our aim is to build a community of rammed earth houses.”